1.Basic parameters

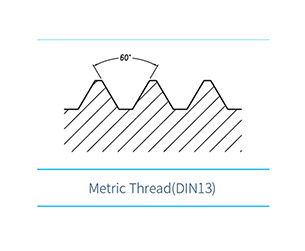

Thread specification: diameter of 8 mm and pitch of 1 mm.

Thread length: 70 indicates that the length of the threaded part on the lead screw is 70 mm.

Total length of the lead screw: 120 indicates that the overall length of the lead screw is 120 mm.

Lead: For this sliding lead screw, the lead is equal to the pitch, which is 1 mm.

Thread hand: Right-hand thread

2.Performance Characteristics

Transmission efficiency: Due to sliding friction transmission, the efficiency is relatively low, usually around 30% - 50%.

Accuracy:According to common accuracy classification, it is mostly used in scenarios where precision requirements are not extreme, such as ordinary machine tool feed mechanisms (specific accuracy needs to be judged in conjunction with production standards, etc.).

Self-locking property: It has a certain self-locking ability, which can maintain position stability to a certain extent without the need for additional locking devices.

Wear resistance: After long-term use, sliding friction between the lead screw and nut will cause wear, which affects transmission accuracy and service life.

Advantages:

This model of lead screw has a nominal diameter of only 8 mm, which is a small specification, and adopts M8×1 ordinary metric threads (with a triangular thread profile and mature processing technology). It does not require complex special structures such as ball circulation channels and high-precision ball grooves (different from ball screws).

Whether it is thread processing by lathe, milling of positioning surfaces, or injection molding/machining of matching nuts, no high-precision special equipment is needed. The manufacturing cost is 30%-50% lower than that of ball screws of the same specification, making it very suitable for small equipment sensitive to cost (such as the feed mechanism of household 3D printers and small manual adjustment platforms).

The sliding lead screw relies on sliding friction transmission between the lead screw and the nut, and the fine thread of M8×1 (with a pitch of 1 mm and a small thread lead angle) further enhances the self-locking ability. When an axial load acts on the nut, the friction between the threads can offset the load, eliminating the need for additional positioning devices such as brakes and locking cylinders.

It is especially suitable for light-load scenarios with vertical or inclined installation (such as small lifting platforms and micro clamps), which can prevent position deviation caused by load falling when power is cut off or the machine is shut down, and simplify the overall structural design of the equipment.

Unlike ball screws that require strict protection of the ball circulation system (to avoid jamming of balls by dust and debris), the thread matching surface of this sliding lead screw is in open contact. Moreover, the small-specification M8 thread has a small gap, so a small amount of dust or debris can be discharged through the tiny gap on the thread flank, and "seizure" faults are less likely to occur.

In dusty scenarios (such as small wood carving machines and simple material pushing devices), there is no need to install additional dust covers or sealing rings, resulting in lower maintenance costs and a failure rate 20%-30% lower than that of ball screws in the same environment.

Disadvantages:

Extremely Low Transmission Efficiency, Prominent Energy Consumption and Heating Issues

For scenarios requiring continuous operation or high-frequency reciprocating motion (such as the high-frequency feed mechanism of small automated equipment), the temperature of the matching surface between the lead screw and the nut will rise by 5-15℃ after long-term operation. This not only causes the thread gap to increase due to thermal expansion (affecting positioning accuracy) but also may accelerate the failure of the grease due to high temperature, requiring frequent lubrication replenishment (usually, grease needs to be reapplied every 100 hours, while ball screws only need replenishment every 500 hours).

Affected by sliding friction and wear, the lead screw of this model will experience wear on the thread matching surface after long-term use (usually after 1000-2000 hours of operation), resulting in increased backlash (the initial backlash is about 0.1-0.2 mm, which may expand to 0.3-0.5 mm after wear). The positioning accuracy can usually only reach ±0.1 mm (the ball screw of the same specification can reach ±0.01 mm).

In addition, the small-specification M8 lead screw has low rigidity (the axial rigidity is about 50-80 N/μm, which is only 1/3-1/2 of that of the ball screw of the same specification). It is prone to elastic deformation when subjected to axial loads, which further reduces the repeat positioning accuracy and makes it unable to meet the needs of precision machining (such as micro-part drilling and fine-tuning of precision measuring instruments).

The lead screw with a nominal diameter of 8 mm has a small cross-sectional area (about 50.27 mm²), and the stress surface of sliding friction is only the thread flank. The maximum long-term axial rated load it can bear is usually no more than 500 N (about 50 kgf, while the ball screw of the same specification can reach more than 1500 N).

If it is used in scenarios where the load exceeds the rated value (such as lifting small heavy objects), it will not only accelerate thread wear but also may cause plastic deformation of the lead screw (such as crushing of thread teeth) or even fracture, posing potential safety hazards.

English

English